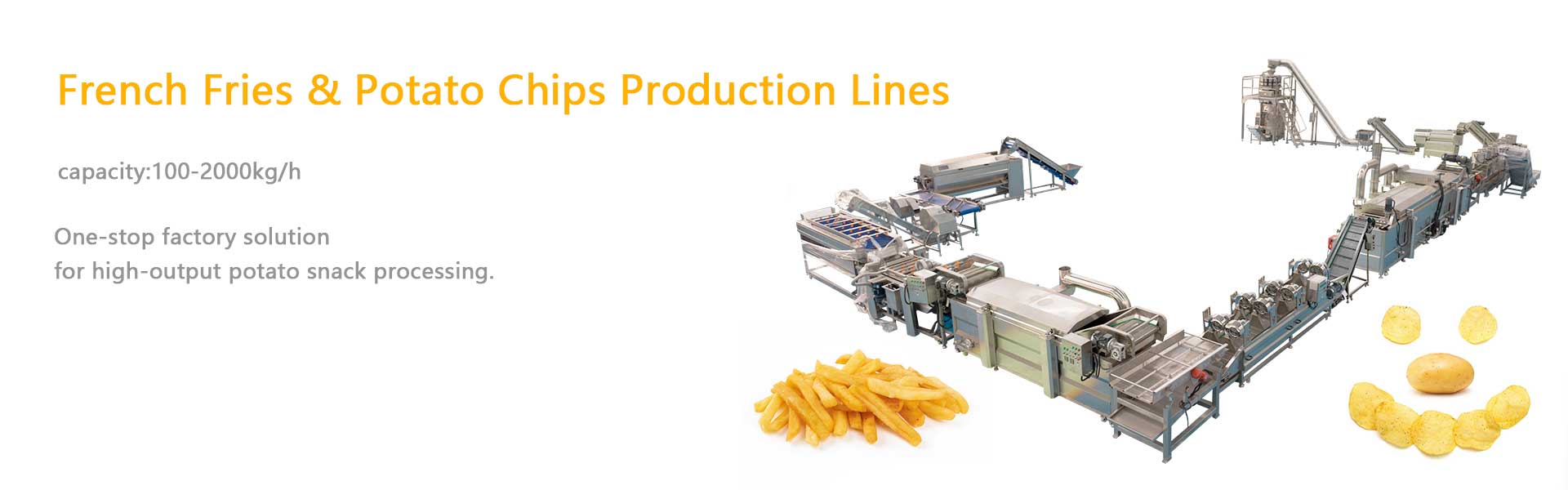

Fully Automatic French Fries Production Line

Description:

Joyshine automatic frozen French fries production line is designed for industrial-scale production, covering every step from potato washing to final frozen packaging. Built with SUS304 stainless steel and equipped with reliable PLC control system, the line ensures stable performance, food safety, and easy operation. Available in capacities from 100kg/h to 5000kg/h, it can be fully customized to meet your factory needs.- Description

- Advantage

- Parameters

- Application

- Video

Automatic Frozen French Fries Production Line | Joyshine

Joyshine provides a complete automatic frozen French fries production line, covering every step from raw potato washing to final frozen packaging. As a source manufacturer, we design and build all equipment in-house to ensure stable performance, hygienic standards, and long-term reliability for industrial-scale production.

Flexible Capacity Options

Our lines are available with output capacities from 100kg/h up to 5000kg/h, fully customizable according to your factory size, automation level, and market demand. Whether you are building a new frozen French fries plant or upgrading an existing line, Joyshine delivers the most suitable turnkey solution.

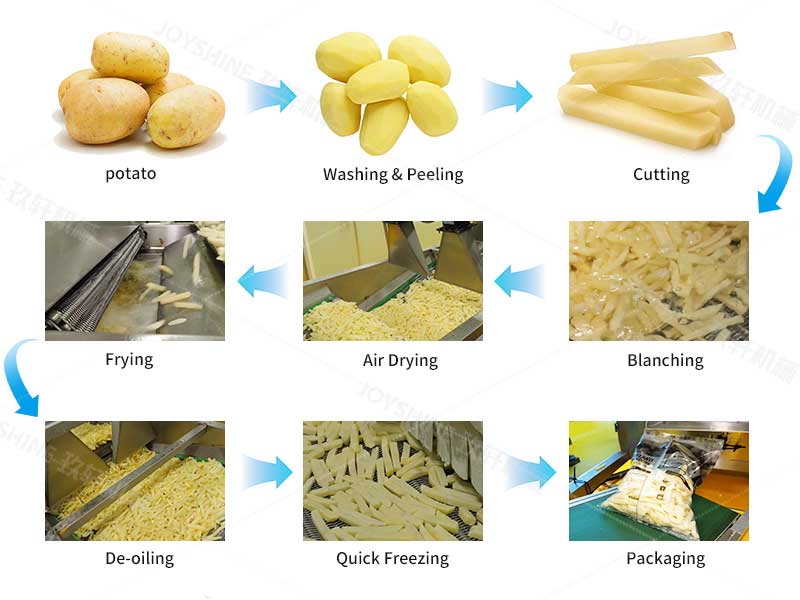

Standardized Production Workflow

Fresh potato washing & peeling → Sorting & cutting → Blanching → De-watering → Continuous frying → De-oiling & cooling → Freezing → Automatic weighing & packaging

Built to International Standards

All equipment is manufactured with SUS304 stainless steel and equipped with high-quality components such as Schneider electrical elements and RIELLO/BALTUR burners. The line complies with CE, FDA, and ISO certifications, ensuring consistent production of premium frozen French fries for both domestic distribution and export markets.

Value to Your Business

Energy Saving: Optimized heating and frying systems reduce energy consumption by 15–20%.

Labor Reduction: Fully automated control system helps cut labor costs by 30–40%.

High Output Stability: Designed for 24/7 continuous production, meeting large-scale order requirements.

Proven Worldwide: Joyshine French fries lines have been successfully delivered to 40+ countries, helping food factories worldwide achieve profitable growth.

Joyshine delivers not only machinery, but also a profitable frozen French fries plant for your business.

Advantage

- 1. Flexible Capacity & Customization – 100–5000kg/h, tailored to your production needs, with factory layout planning support.

- 2. High Efficiency & Automation – Reduces labor 30–40%, supports 24/7 continuous production.

- 3. Consistent Quality & Food Safety – SUS304 stainless steel and PLC control ensure uniform fries and hygiene.

- 4. Energy & Cost Savings – Optimized fryer lowers energy consumption by 15–20%.

- 5. Easy Operation & Maintenance – User-friendly interface, minimal downtime.

- 6. Turnkey Solutions & Support – Complete line design, installation, and technical support for smooth operation.

Parameters

|

No. |

Name |

Quantity |

|

1 |

Elevating Conveyor |

1 set |

|

2 |

Potato Washing and Peeling Machine |

1 set |

|

3 |

Picking Line |

1 set |

|

4 |

Potato Cutting Machine/french fries cutting machine |

1 set |

|

5 |

Potato sticks pre washing machine |

1 set |

|

6 |

Chips roller picking machine |

1 set |

|

7 |

Bubble Washing Machine |

1 set |

|

8 |

Blanching Machine |

1 set |

|

9 |

Air Drying Machine |

1 set |

|

10 |

Elevating Conveyor |

1 set |

|

11 |

Continuous Belt Frying Machine |

1 set |

|

12 |

Vibrating Deoiling Machine |

1 set |

|

13 |

Air Drying Machine |

1 set |

|

14 |

Elevating Conveyor |

1 set |

|

15 |

Freezing Machine |

1 set |

|

16 |

Automatic Packing Machine |

1 set |

Application

1. Industrial-Scale French Fries Production – Designed for factories and businesses requiring high-volume French fries or potato chips production, whether building a new line or expanding existing capacity.

2. Versatile Vegetable & Fruit Processing – Suitable for root vegetables such as sweet potatoes, cassava, taro, yam, and even some fruits like bananas, offering flexible production solutions for diverse product lines.

3. Expandable & Customizable – Supports production upgrades, factory layout adjustments, and seamless integration with existing lines for scalable operations.

Video

More info

Thank you for visiting our website! We endeavors to produce food machinery, potato chips, banana chips, chicken process, etc. If you have any question, please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.We regularly attend kinds of exhibition, which let more customers understand our products, quality and service. Through these exhibition, we established long-term cooperation with many customers from Europe, Asia, South America and many other regions and countries. Customer feedback: