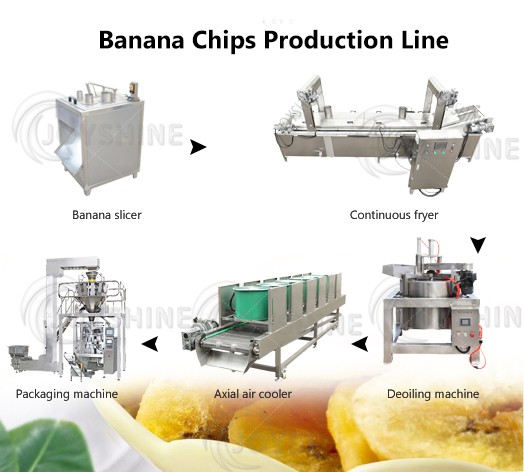

Banana Chips Production Line

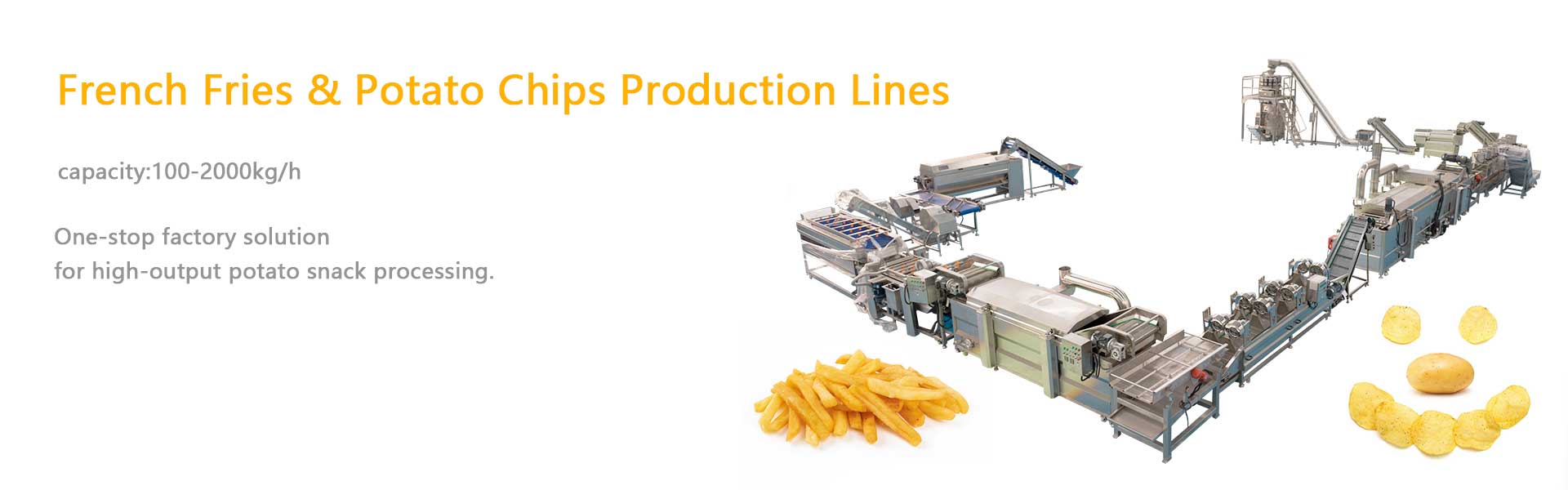

Banana chips are primarily produced from unripe bananas, processed through frying techniques. To accommodate diverse production demands, we offer a variety of capacity options, including but not limited to 100 kg/hour, 150 kg/hour, 200 kg/hour, 300 kg/hour, and 500 kg/hour. We are capable of providing customized output capacity solutions based on the specific requirements of our clients.

- Description

- Advantage

- Parameters

- Application

- Video

Discover the advanced Banana Chip Production Line developed by Joyshine, designed to meet the needs of efficient, automated Fried Banana Chip Production. Constructed with premium 304 stainless steel and a PLC electrical control system, our Banana Chip Manufacturing Machinery aims to provide industry-leading technological solutions, ensuring safety and efficiency throughout the production process. Incorporating imported stainless steel bearings and internationally renowned brand electrical components, Joyshine's production lines exceed domestic standards in technical levels, guaranteeing exceptional product quality.

The Banana Chip Production Line is available in two main types to accommodate different scales of production requirements and budgets:

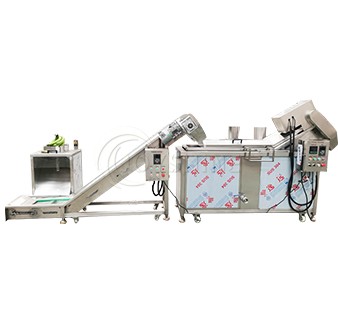

Semi-Automatic Banana Chip Production Line:

This includes essential equipment such as slicers, elevators, fryers, de-oiling machines, and seasoning machines, offering various heating methods to enhance production efficiency. It is the ideal choice for startups and clients with limited budgets. With a capacity range from 50kg/h to 100kg/h, it perfectly meets the needs of small-scale processing plants.

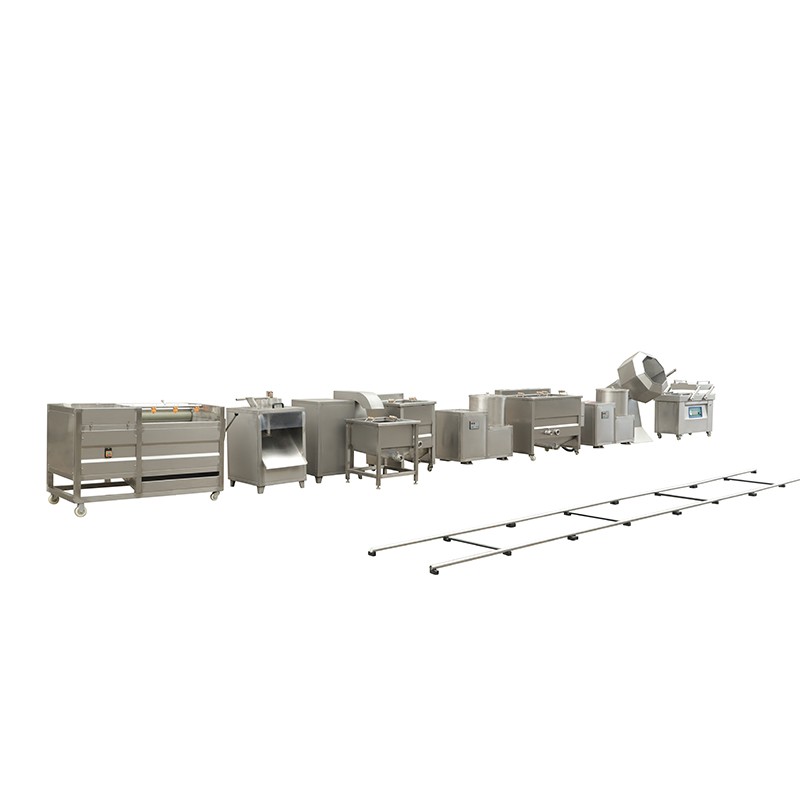

Fully Automatic Banana Chip Production Line:

Comprising a complete set of equipment including peeling machines, sorting machines, slicers, blanching machines, elevators, drying machines, fryers, de-oiling machines, seasoning machines, and packaging machines, this line achieves full automation of the production process. Aimed at enterprises with rich industry experience and sufficient budgets, this line offers high automation levels, significantly reducing labor costs, enhancing productivity and product quality, and achieving precise control over temperature and time.

Purchasing your Banana Chip Production Line directly from the manufacturer Joyshine means you can enjoy more competitive prices than those offered by competitors. We commit to providing our clients with professional, efficient, and customized production line solutions, maximizing your investment return.

Choose Joyshine's Fried Banana Chip Production Line and let us embark on a new chapter of high-quality banana chip manufacturing together.

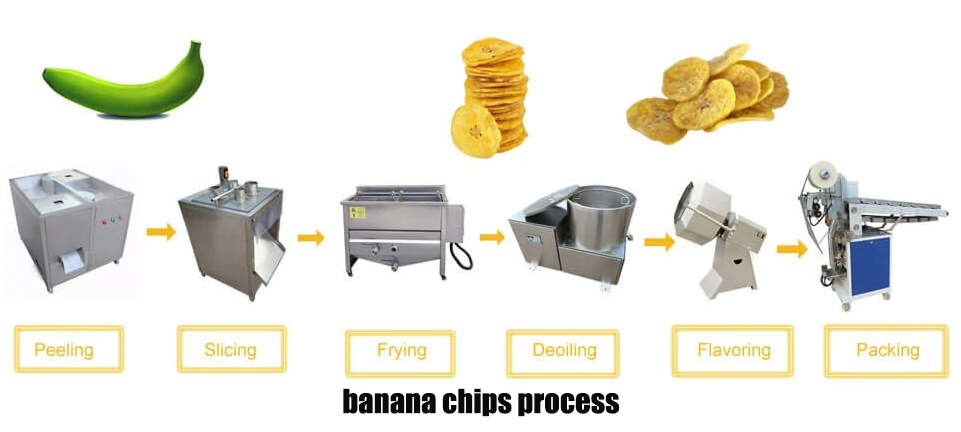

Work flow

Raw material peeling machine → Banana slicer → Continuous frying machine → Vibrating de-oil machine → Air drying machine → Automatic weighing and packaging machine

Key Equipment Introduction for the Fried Banana Chips Production Line:

Banana slicing machine: Equipped with high-precision, sharp blades to ensure uniform and consistent slicing of bananas. The adjustable slicing thickness ranges from 3 to 5 millimeters to meet the specific needs of different customers, providing standardized semi-finished products for subsequent processing.

Elevator feeding machine: Responsible for conveying the sliced banana chips to the frying equipment, optimizing the continuity of the production process.

Banana chips frying machine: Features an automated production line design that uniformly fries the banana chips to a golden and crispy texture in constant temperature oil, reducing moisture content to 2%, enhancing flavor and crispiness.

Banana chips de-oiling machine: Efficiently removes excess oil from the surface of the fried banana chips, ensuring the product's taste and health standards.

Elevator feeding machine: Precisely conveys the fried banana chips to the seasoning stage, maintaining production efficiency and quality.

The seasoning machine: Offers a variety of seasoning options to meet market and customer demands for different flavored banana chips, increasing product diversity.

Picking line: Ensures the quality of the processed banana chips, effectively conveying qualified products to the packaging stage.

Automatic banana chips packing machine: Automates the processes of measuring, filling, sealing, date printing, and outputting finished products, achieving an efficient packaging process for the production line.

Advantages of Our Banana Chips Production Line

- 1. Customizable Banana Chips Production Capacity: Our banana chips production line is designed with flexibility, allowing customization according to client needs. Whether for small-scale production (starting from 50kg/h) or large-scale production requirements (up to 500kg/h), our banana chips manufacturing machine meets your demands.

- 2. High-Quality Materials and Premium Components: We focus on the quality of our banana chips production line, utilizing high-standard SUS304 stainless steel for all equipment to ensure durability and food safety. Electrical components are sourced from renowned international brands such as Schneider or Chint, further ensuring the stability and reliability of our banana chips manufacturing machine.

- 3. Versatile Heating Solutions: Our banana chips production line offers various heating options, including electric heating, gas heating, and diesel heating, equipped with top-tier RIELLO or BALTUR burners to accommodate different production environments and energy requirements.

- 4. Precise Banana Chip Thickness Adjustment: Our banana chips manufacturing machine allows for precise thickness adjustments of banana chips, ranging from 1mm to 5mm, to meet market demands for different thicknesses.

- 5. Professional Flavoring Techniques: Catering to the demand for various flavors, our banana chips production line is equipped with professional flavoring equipment, enabling easy preparation of banana chips in diverse flavors.

- 6. High-Efficiency and Energy-Saving Frying Technology: Our specially designed frying machine not only heats up quickly but also operates with high energy efficiency, significantly enhancing the production efficiency of the banana chips production line while reducing energy consumption.

Parameters

|

No. |

Name |

Quantity |

| 1 | Banana Slicer | 1 set |

| 2 |

Continuous Belt Frying Machine |

1 set |

| 3 | Deoiling And Dewatering Machine | 1 set |

|

4 |

Air Drying Machine |

1 set |

| 5 |

Automatic Packaging Machine |

1 set |

Banana Chips Production Line Application

Our banana chips production line is designed with flexibility to accommodate processing needs of various scales, efficiently operating from small workshops to large production facilities. Based on your workshop area and production requirements, we offer customized solutions aimed at maximizing your production efficiency and economic benefits.

Wide Processing Range: In addition to banana chips, our equipment can process a wide variety of fruits and vegetables, such as potato chips, sweet potato chips, cassava chips, etc., with a particular expertise in handling diverse types of root vegetables. This versatility ensures that our banana chips manufacturing machine can meet the extensive market demands for processing various fruits and vegetables.

Video

More info

Thank you for visiting our website! We endeavors to produce food machinery, potato chips, banana chips, chicken process, etc. If you have any question, please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.We regularly attend kinds of exhibition, which let more customers understand our products, quality and service. Through these exhibition, we established long-term cooperation with many customers from Europe, Asia, South America and many other regions and countries. Customer feedback: