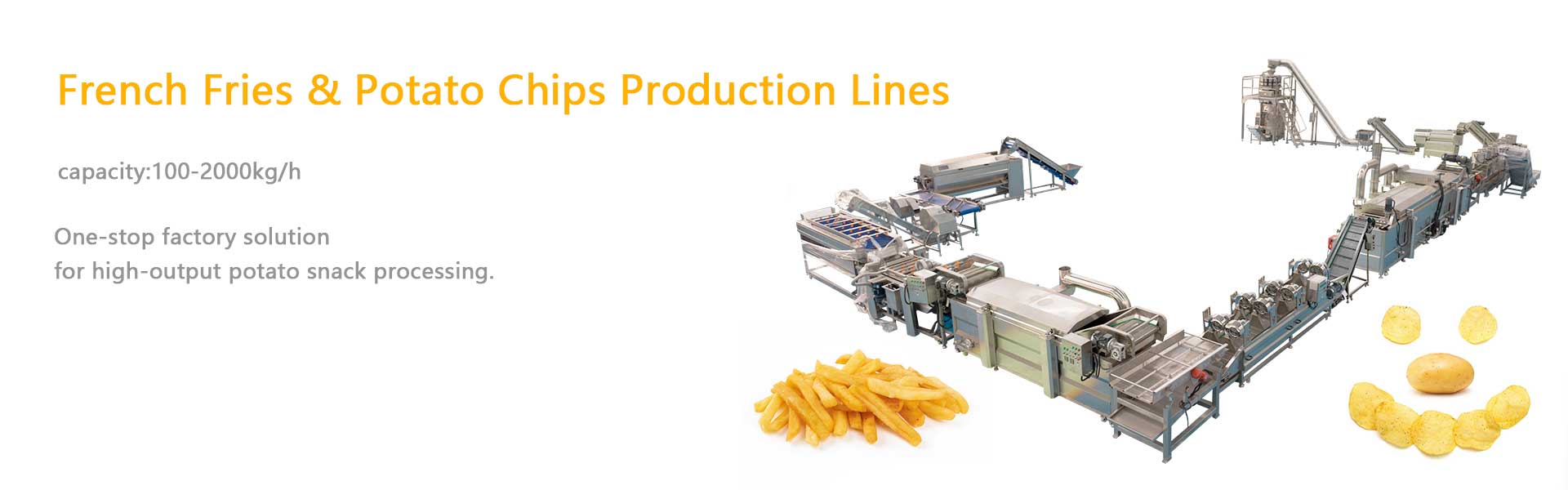

Fully Automatic Potato Chips Production Line

Description:

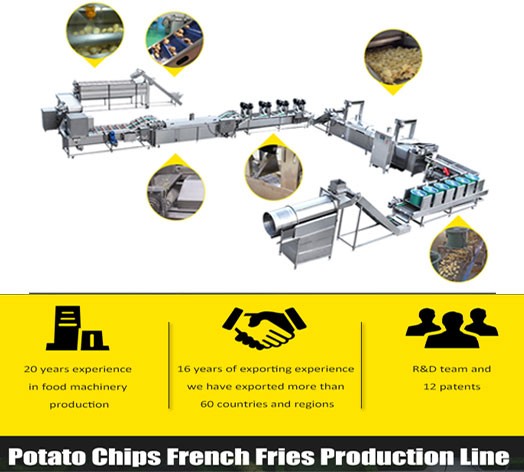

This set of production line is a new type of potato chip potato production line developed by Joyshine. This production line is made of high quality 304 stainless steel, PLC electrical control, high technical content, safe and efficient the bearings are imported stainless steel bearings, electrical appliances. The use of imported brand-nane products, the technical level of domestic leading.Advantage

- 1. French freis process capacity (finished capacity 100kg/h to 2000kg/h),potato chips process capacity(finished capacity 50kg/h to 500kg/h)and work flow can be customized.

- 2. All equipment are made of SUS304, electrical apparatus element are Schneider brand or CHINT brand.

- 3. Heating method: Electric heating, Gas heating or Diesel heating (equipped with RIELLO or BALTUR burner), etc.

- 4. The size of French fries and the thickness of potato chips are adjustable.

- 5. For French fries line, we have special equipment to remove the unqualified fries.

- 6. With special designed fryer, quick heating and energy saving, enabled good performance.

- Description

- Advantage

- Parameters

- Application

- Video

Description

The industrial potato chip plant is a perfect production line to produce good quality potato chips or potato crisps. Our industrial potato chips equipment has become the most popular product both domestically and abroad. Meanwhile, it has the following features: high automatichigh efficiency and energy-saving. Output capacities for choices, potato chips production: 50kg/h, 100kg/h, 150kg/h, 200kg/h, 300kg/h, 500kg/h. Different capacities can be customized based on your own needs. At the same time, we can offer the best suitable solutions to you.

This set of production line is a new type of potato chip production line developed by Joyshine. The material of equipment is made of high quality 304 stainless steel. And it adpots PLC electrical control and high technical content in order to operate safely and efficiently. The bearings are imported stainless steel bearings, electrical appliances. The use of imported brand-nane products, the technical level of domestic leading.

Work flow

Fresh potato elevator → Potato washing and peeling machine → Unqualified potato picking line → Potato chips cutter or slicing machine) → Potato chips pre-washing elevator with water tank → Unqualified fries picking line → Potato chips washing machine → Blanching machine →Vibration de-water machine → Potato chips continuous frying machine → Vibrating de-oil machine → Automatic weighing and packaging machine

Details of different functions for different process

- Potato elevator:

Used to transfer the fresh potatoes into the cleaning and peeling machine in large quantity. This machine is optional for some chips making factory.

- Clearing and peeling machine:

Used to wash the fresh potatoes and peel the skin automatically without damage.

- Potato Cutting or slicing machine:

Cut the potatoes into chips, wave chips by changing different knives. The thickness of the chips is adjustable by your needs.

Used to prepare for frying chips in order to make the color taste better and make the chips crispy.

- Vibration dewatering machine:

Used to remove the extra water on the surface of the chips by high-frequency vibration after blanching process.

- Air Blowing de-watering machine:

Used to reduce the water contained in the chips, thus it will be easier to be fried.

For the potato chips need to be totally fried to make it crisper so that you need to adjust the frying time.

- Air blowing de-oiling machine:

Totally remove the oil on the surface of the chips.

It is to mix the flavor to the surface of the chips to get different taste chips to cover more consumers.

Used to pack the final products. Our fully automatic packing machine can feed, elevate, weigh and pack the potato chips automatically so as to reduce labor cost.

Advantages of the Fully Automatic Potato Chips Production Line

Our fully automatic potato chips production line is designed to meet high standards of production needs, offering various production capacities ranging from 50 kg/h to 500 kg/h. The workflow and machine configurations can be customized to meet specific customer requirements. Here are the main advantages of our production line:

- High-Quality Materials: All production equipment is made from high-quality SUS304 stainless steel, ensuring durability and compliance with food safety standards. Electrical components are from internationally recognized brands such as Schneider or Chint, ensuring stability and reliability.

- Diverse Heating Options: We offer multiple heating methods, including electric heating, gas heating, and diesel heating, equipped with top-tier RIELLO or BALTUR burners. This accommodates different regional energy availabilities and preferences.

- Adjustable Chip Thickness: The thickness of the chips can be adjusted to meet production requirements, catering to varying market consumer preferences.

- Quality Control: Equipped with specialized equipment to automatically remove defective chips, ensuring the final product quality meets standards.

- Efficient Frying System: The frying pot is specially designed for rapid heating and high energy efficiency, effectively saving energy while maintaining the quality of frying.

By using our fully automatic potato chips production line, customers can not only increase production efficiency but also ensure consistency and quality of the product, making it an ideal choice for investing in the food production industry.

Parameters

|

No. |

Name |

Quantity |

|

1 |

Elevating Conveyor |

1 set |

|

2 |

Potato Washing and Peeling Machine |

1 set |

|

3 |

Picking Line |

1 set |

|

4 |

Potato Cutting/Slicing Machine |

1 set |

|

5 |

Potato Chips pre washing machine |

1 set |

|

6 |

Chips roller picking machine |

1 set |

|

7 |

Bubble Washing Machine |

1 set |

|

8 |

Blanching Machine |

1 set |

|

9 |

Air Drying Machine |

1 set |

|

10 |

Elevating Conveyor |

1 set |

|

11 |

Continuous Belt Frying Machine |

1 set |

|

12 |

Vibrating Deoiling Machine |

1 set |

|

13 |

Air Drying Machine |

1 set |

|

14 |

Elevating Conveyor |

1 set |

|

15 |

Freezing Machine |

1 set |

|

16 |

Automatic Packing Machine |

1 set |

Application

1. Our production line is designed with flexibility to accommodate processing workshops of various sizes for potato chips and banana slices. We offer customized solutions tailored to your workshop area to optimize your production line equipment layout.

2. Additionally, this production line is capable of processing a wide range of fruits and vegetables, particularly specializing in root and tuber vegetables such as potatoes, carrots, and beets. It provides diverse processing capabilities to meet broad market demands.

Video

More info

Thank you for visiting our website! We endeavors to produce food machinery, potato chips, banana chips, chicken process, etc. If you have any question, please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.We regularly attend kinds of exhibition, which let more customers understand our products, quality and service. Through these exhibition, we established long-term cooperation with many customers from Europe, Asia, South America and many other regions and countries. Customer feedback: