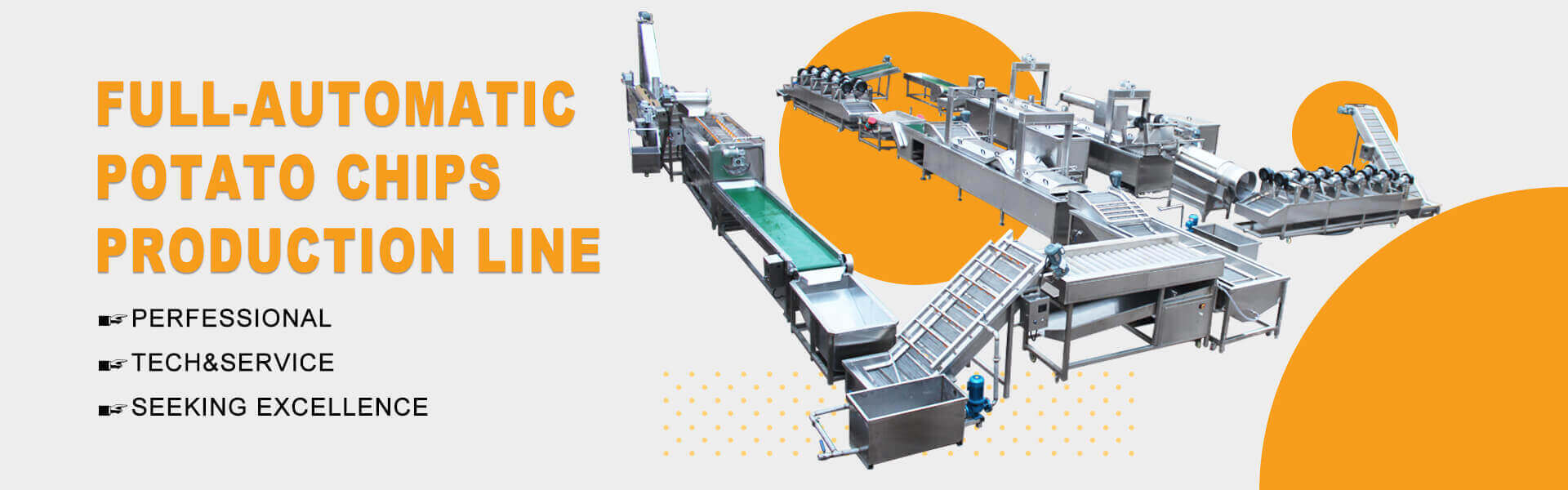

Fried Puffed Snack Food Processing Line

Description:

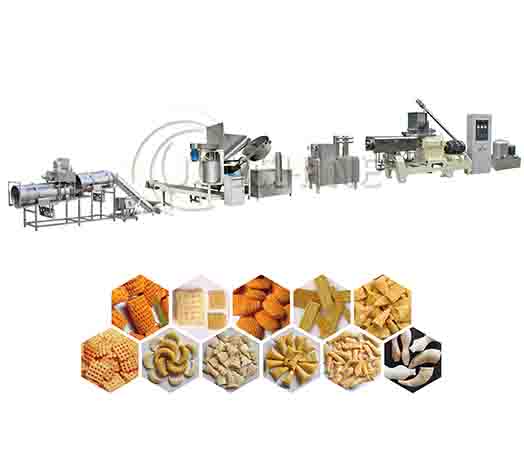

Fried puffed production line can make different kinds fried snacks based on changing die moulds and manufaturing technique. The process includes muxing, ectruding, cutting, frying, flavoring and packing. The products are crispy and less oil.Advantage

- 1. Capacity: 100kg/h -500kg/h and work flow can be customized.

- 2. Raw materials: all kinds of grain powder, such as wheat flour, corn powder, rice powder and so on.

- 3. Products: Rice crusts, chips, bulges, pizza, rolls, doritos, kurkure, cheetos, etc.

- 4. Production line of work flow: Mixer--- Screw Conveyor ---- Double Screw Extruder --- Compound Cutting Machine --- Auto Fryer --- Double Roller Flavor Machine --- Packaging Machine

- Description

- Advantage

- Parameters

- Application

- Video

Introduction of fried puffed snack food processing line

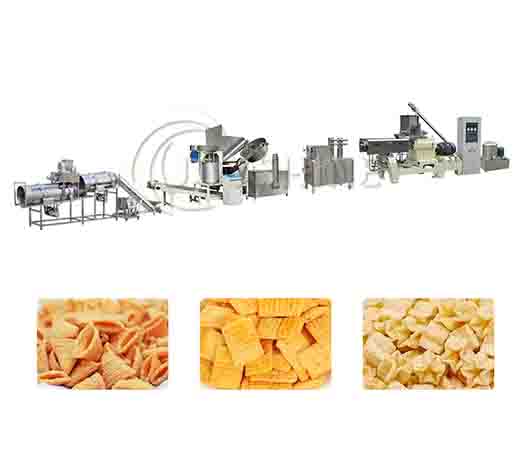

Fried puffed snack food processing line takes wheat flour, corn powder and rice powder as main materials. After extruding, it can be cut into many differernt shapes of products like strip, flake or trangle. After frying and flavouring, it becomes crispy and delicous fried puffed snacks with delicate texture. This snacks food line can be done fully automatically from mixing, extruding to frying and flavouring.

The capacity is from 120kg/h to 250kg/h. We also offer customized service.

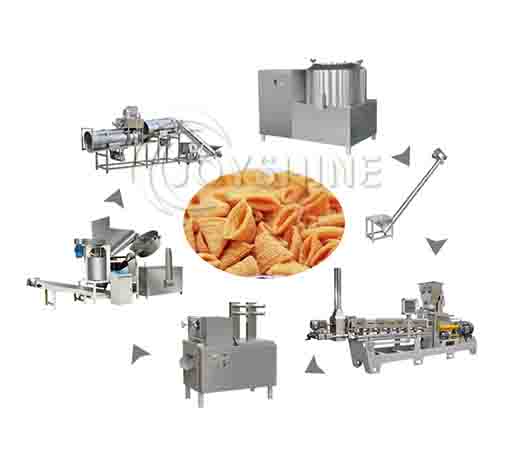

Production line of work flow:

Mixer--- Screw Conveyor ---- Double Screw Extruder --- Compound Cutting Machine --- Auto Fryer --- Double Roller Flavor Machine --- Packaging Machine

Advantage

A. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting.

B. Gearbox with automatic lubrication function, extending gear life.

C. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

D. Production line is fully automatic, only need 1-2 persons to operate.

Fried puffed snack food making machine parameters

| Equipment Name | Function |

| Mixer | Mix the material together |

| Screw conveyor | Conveying the material into the extruder |

| Twin-screw extruder | Extruding & puffing&shaping snacks |

| Cutting&Shaping machine | Cut &Shape the snacks |

| Food Grade PVC Hoister | Conveying the snack chips to frying machine |

| Continuous fryer | Frying snack chips |

| Deoiling machine | Remove the extra oil on the snack |

| Flavoring line | Spraying oil and seasoing powder on the snacks |

| Whole line Length | 20-25m |

| Voltage and frequency |

we can make it according to customers' local voltage according to different countries. |

Application

Raw material: all kinds of grain flour

1. Small food processing plant, snack food factory, fruit processing plant.

2. Hotels, snacks store, small snack plant etc.

Video of puffed snacks making machine

More info

Thank you for visiting our website! We endeavors to produce food machinery, potato chips, banana chips, chicken process, etc. If you have any question, please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.We regularly attend kinds of exhibition, which let more customers understand our products, quality and service. Through these exhibition, we established long-term cooperation with many customers from Europe, Asia, South America and many other regions and countries. Customer feedback: