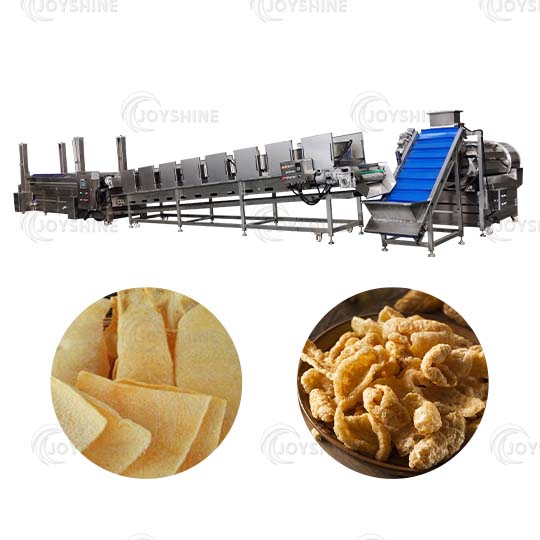

Fried pork skin production line

Crispy pork rinds are a globally popular snack, known for their crunchy texture and rich flavor. Joyshine’s advanced pork rind frying production line offers a one-stop solution for food manufacturers, covering cleaning, cutting, skinning, frying, and packaging. The production line ensures efficient and uniform frying, delivering consistently high-quality products and enhancing production efficiency, making pork rind snacks even more delicious and appealing.

- Description

- Advantage

- Parameters

- Application

- Video

Fried pork rinds, a popular gourmet snack around the world, are known for their crispy texture and rich flavor. In order to meet the demand for efficient production, we have launched an advanced fried pork rind production line, aiming to provide a one-stop solution for food production enterprises. From cleaning, cutting, stripping and frying pork skin to final packaging, it is ensured that each piece of pork skin can be fried evenly to achieve the ideal crispy effect. This production line not only greatly improves production efficiency, but also ensures consistent product quality, making your pork skin snacks more delicious.

Semi-automatic production line: 20-100kg/h

Fully automatic production line: 100-500kg/h

Option one:

Raw material processing: Use dried pig skin, wash it thoroughly, and fry it directly in oil at 180 degrees for 5-6 minutes.

Efficiency and environmental protection: The output to raw material ratio is 3:1. This solution not only does not consume extra oil, but also produces grease, making efficient use of resources.

Option II:

Complete processing process: including scraping, cutting, washing, drying, frying, de-oiling, seasoning, and packaging. The processing temperature is controlled at 220 degrees, the processing time of each batch is about 30-40 seconds, and the output ratio is 1:1.

Versatility: Adaptable to different market needs and can be customized according to customers' specific requirements, such as flavors and packaging.

Fried pork skin processing flow

Most customers tend to purchase semi-finished products, that is, pre-treated dried pork rinds, which are directly fried, simplifying the traditional processing process.

Detailed processing flow:

Frying: Put the cleaned pork skin into 190-degree oil and fry it for about 30 seconds to quickly obtain a crispy exterior and tender inside.

De-oiling treatment: Use an axial flow fan to remove excess fat in a short time to ensure product quality.

Seasoning: According to market requirements and customer tastes, carry out fine seasoning processing, including powder seasoning, liquid seasoning and coating.

Packaging: The final step, automatic weighing and packaging according to market demand.

This production line design aims to provide efficient and customizable solutions that adapt to different customer needs and ensure high product quality, from raw materials to finished products.

Joyshine Fried Pork Skin Production Line - Core Advantages

Efficient production: Double-layer mesh belt conveyor system ensures uniform frying, improves efficiency several times, and reduces labor demand.

Advanced technology: SUS304 stainless steel structure, durable and safe. Efficient combustion chamber and precise temperature control system optimize thermal efficiency and reduce heat loss.

Fully automated: automatic feeding, unloading, temperature control and filtration, reduce manual intervention, and eliminate secondary pollution.

Safe and reliable: Equipped with Schneider and Siemens electrical components, the operation is safer.

Energy saving and environmental protection: Shallow oil tank design saves fuel consumption and meets environmental protection requirements.

High-quality finished products: Provide stable product taste and color, and ensure high quality standards.

Joyshine Fried Pork Skin Production Line integrates efficiency, safety and environmental protection, providing food companies with cost-effective solutions and facilitating large-scale production of high-quality products.

| NO. | Name | Quantity |

| 1 | Lift conveyor | 1 set |

| 2 | Continuous frying machine | 1 set |

| 3 | Air cooling line | 1 set |

| 4 | Drum Seasoning Machine | 1 set |

| 5 | Packing Machine | 1 set |

The above configuration is for reference, we can customize the machines on the production line according to user needs

Versatility and wide range of applications:

The Joyshine fried pork rinds production line is designed to be suitable for food production companies of all sizes, especially for production environments that pursue high efficiency, low cost and high quality. In addition to pig skins, this production line can also process a variety of other fried foods, such as chicken skins, fish skins and potato chips, ensuring that each processed food has the best flavor and texture.

Market potential and technical support:

As the demand for fried pork rinds continues to grow, there is an increasingly strong demand for high-quality fried products in the market, providing huge business opportunities for food production companies. Joyshine not only provides mature pigskin processing equipment, but also provides full technical guidance and training to help customers quickly establish their brands and enhance market competitiveness.

Affordable and customizable:

The production line's simple production process and low equipment investment and raw material costs make it an economical choice. In addition, the Joyshine fried pork rinds production line supports product customization and can be adjusted according to different market needs to meet a wider range of customer needs.

Welcome to inquire for more details and discover how you can use the Joyshine Fried Pork Rinds Production Line to bring growth and success to your business.

Video of vegetable and fruit cleaning and drying line

More info

Thank you for visiting our website! We endeavors to produce food machinery, potato chips, banana chips, chicken process, etc. If you have any question, please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.We regularly attend kinds of exhibition, which let more customers understand our products, quality and service. Through these exhibition, we established long-term cooperation with many customers from Europe, Asia, South America and many other regions and countries. Customer feedback:

hot products

nodata