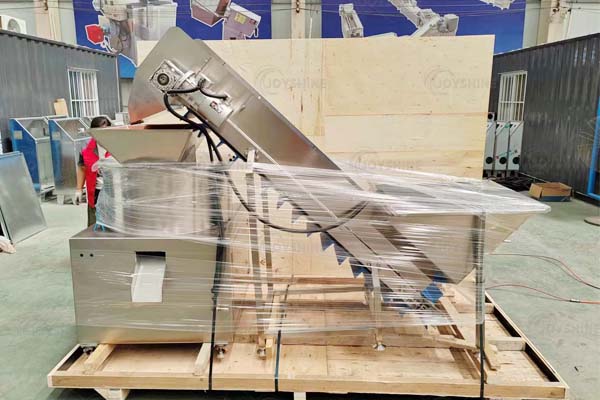

Today, Joyshine successfully shipped a potato washing and peeling production line to a Polish customer, further demonstrating our competitiveness and customer trust in the global market.

Production line details

The production line shipped this time includes the following four equipment:

Roller pre-washer: used for preliminary washing of potatoes to remove dirt and impurities on the surface.

Elevator: transports potatoes from the pre-washer to the peeler, saving labor and improving production efficiency.

Peeler: uses advanced peeling technology to efficiently remove the potato skin and ensure that the potatoes are clean and free of impurities.

Roller conveyor: transports the peeled potatoes to the next processing link or packaging area to ensure the continuity of the production line.

The production line is designed to have a production capacity of 500kg/h, which can efficiently process a large number of potatoes to meet the production needs of customers.

Improve production efficiency and help Polish food processing

Poland is an important agricultural producer in Europe, and potatoes are one of the main agricultural products there. Joyshine's potato washing and peeling production line will greatly improve customers' production efficiency, help them better process and utilize potato resources, and contribute to the development of the local food processing industry.

High-quality equipment, customer trust

Joyshine has always been committed to providing high-quality food processing equipment to meet the diverse needs of customers. The equipment shipped this time uses high-quality materials and advanced technology to ensure stable and efficient operation. We thank our Polish customers for their trust and support, and look forward to continuing to provide high-quality equipment and services to global customers in the future.